About Us

Worldwide Presence, fully-staffed Professionals

A bit of our history

Originally established as Flight Test Associates LLC in 1993, Flight Test Aerospace, Inc. (FTA) was incorporated in the State of Delaware in 2008 and maintains its Corporate Headquarters in Chantilly, Virginia and a European Headquarters in Eindhoven, The Netherlands. FTA employs engineers, technicians, mechanics, logisticians, and professional staff working in 6 countries, and maintains fully-staffed offices and warehouse/hangar/production facilities in: U.S.A. (California, Virginia, Tennessee, Alabama), Lebanon, The Netherlands, United Kingdom, United Arab Emirates and Kenya.

FTA’s corporate subsidiaries, all owned by FTA, comprise:

· Black Hall Aerospace, Inc. (BHA Inc.), Huntsville and Meridianville Alabama

· FTAviation LLC, Chantilly, Virginia

· Redstone Aviation Group LLC, Meridianville, Alabama

· FTair LLC, Smyrna and Memphis, Tennessee, and Mojave, California

· FTLogistics LLC, Luray, Virginia

· Flight Test Aerospace Ltd, Nairobi, Kenya

· FTA-UAE, Dubai, United Arab Emirates

· Flight Test Aerospace Ltd, London, United Kingdom

Additionally, the following affiliate of FTA provides the backbone of FTA’s logistics network:

· Prüst Holding B.V., Eindhoven, The Netherlands

FTA is known for its commitment to cost and schedule and for high standards of quality and completion. For this reason, worldwide leaders in aviation have partnered with FTA for top quality aviation engineering, design and support services, namely:

· Boeing – FTA performed CH-47 inspection, corrosion control and painting services. Additionally, performed line maintenance on B-737 aircraft.

· Lockheed-Martin Corporation – FTA provided technical support and advisory services to the U.S. Army Program Executive Office (PEO) for Aviation’s Multi-National Aviation Special Project Office (MASPO).

· BAE Systems – FTA provided certified maintenance personnel and Repair Station services for C-checks on DC-9 aircraft for the U.S. Marine Corps.

· Northrop Grumman Corporation – FTA completed 13 contracts as sole Subcontractor to Northrop Grumman for rotary wing and fixed wing aviation services in Afghanistan, Kazakhstan and Pakistan.

· Raytheon – FTA provided test, evaluation and command & control support to Raytheon flight tests.

· Leidos – FTA provided maintenance, repair and logistics for the Afghanistan Air Force (AAF) fleet of Mi-17 and PC-12 aircraft, as well as a highly successful mentoring and on-the-job (OJT) training program for AAF maintenance and logistics personnel.

· Airbus – FTA performed line maintenance on A-319, A-320 and A-321 aircraft.

· FedEx – FTA provided flight test instrumentation services to FedEx 767 aircraft.

Capabilities

A full-spectrum aviation services business, FTA’s capabilities in support of manned and unmanned aircraft includes:

· Maintenance (Line, Phase and Depot), Repair and Overhaul, including FAA Part 145 Certified Repair Station and EASA Part 145 Certification

· Engineering, Design, Fabrication, Installation and Integration

· Modifications and Upgrades

· Pilot and Aircrew Training

· Cargo Operations - FAA Part 135 Air Carrier and Operator Certification

· Maintenance Technician Mentoring and Training

· Global Logistics Sustainment

· Flight & Engine Test, Evaluation and Certification

· Aviation Facilities Management

Additionally, FTA’s scientists and engineers conduct Research, Development, Test and Evaluation on Sensor Technologies and Perimeter Security/Intrusion Detection System Architecture.

FTA began with a focus on aeronautical engineering and aircraft modifications to include test and evaluation of installed systems on numerous aircraft. FTA’s pioneering efforts included the requisite analysis of structural integrity, aerodynamics, and electronic circuitry pertaining to the installation of external instrumentation and sensor packages required for aircraft Intelligence, Surveillance, and Reconnaissance (ISR) missions. FTA also engineered data acquisition and processing systems to acquire and analyze the data collected by the sensors to include flight test and evaluation of installed systems on numerous fixed-wing and rotary-wing aircraft, as well as the Predator and Pioneer UAVs.

Maintenance, Repair, Overhaul. Having operated in 22 countries on 5 continents, FTA’s extensive experience with organizational and depot level aviation maintenance, systems integration and test, and logistics has enabled the highly efficient and successful completion of U.S. Department of Defense (DoD)/U.S. Army contracts in the U.S., Mexico, Kazakhstan, Pakistan, and Afghanistan, and Direct Commercial Sales contracts in Mexico, Lithuania, Latvia, Hungary, Pakistan, Republic of Tanzania, Rwanda, Cameroon, Burkina Faso, Niger, Democratic Republic of Congo, and Senegal.

Since 2008, FTA has been performing continuously on contracts with the U.S. Army’s PEO for Aviation. A total of 16 PEO Aviation contracts have been completed and FTA continues to support additional PEO Aviation contracts. In support of the U.S. Army PEO Aviation, FTA overhauled the Afghanistan Mi-17 helicopter fleet from 2009 thru 2016 and during 2017 thru 2021 sustained the AAF fleet of 52 Mi-17 and 18 PC-12 aircraft. FTA supported the AAF and Special Mission Wing (SMW) Mi-17/PC-12 fleet with spare parts, technical publications, mentoring/OJT, component overhaul, and direct organizational maintenance and logistics at 4 AAF bases in Kandahar, Kabul, Mazar-e-Sharif and Shindand.

Under two U.S. Army PEO Aviation contracts, FTA completed 31 full aircraft overhauls, including major repairs, for U.S. Army helicopters and helicopters supporting the AAF and Pakistan Army Aviation Command (PAAC).

FTA has also supported 3 Contracts for the U.S. Army’s PEO-STRI and various contingency in support of the U.S. Air Force Aviation Life Cycle Management.

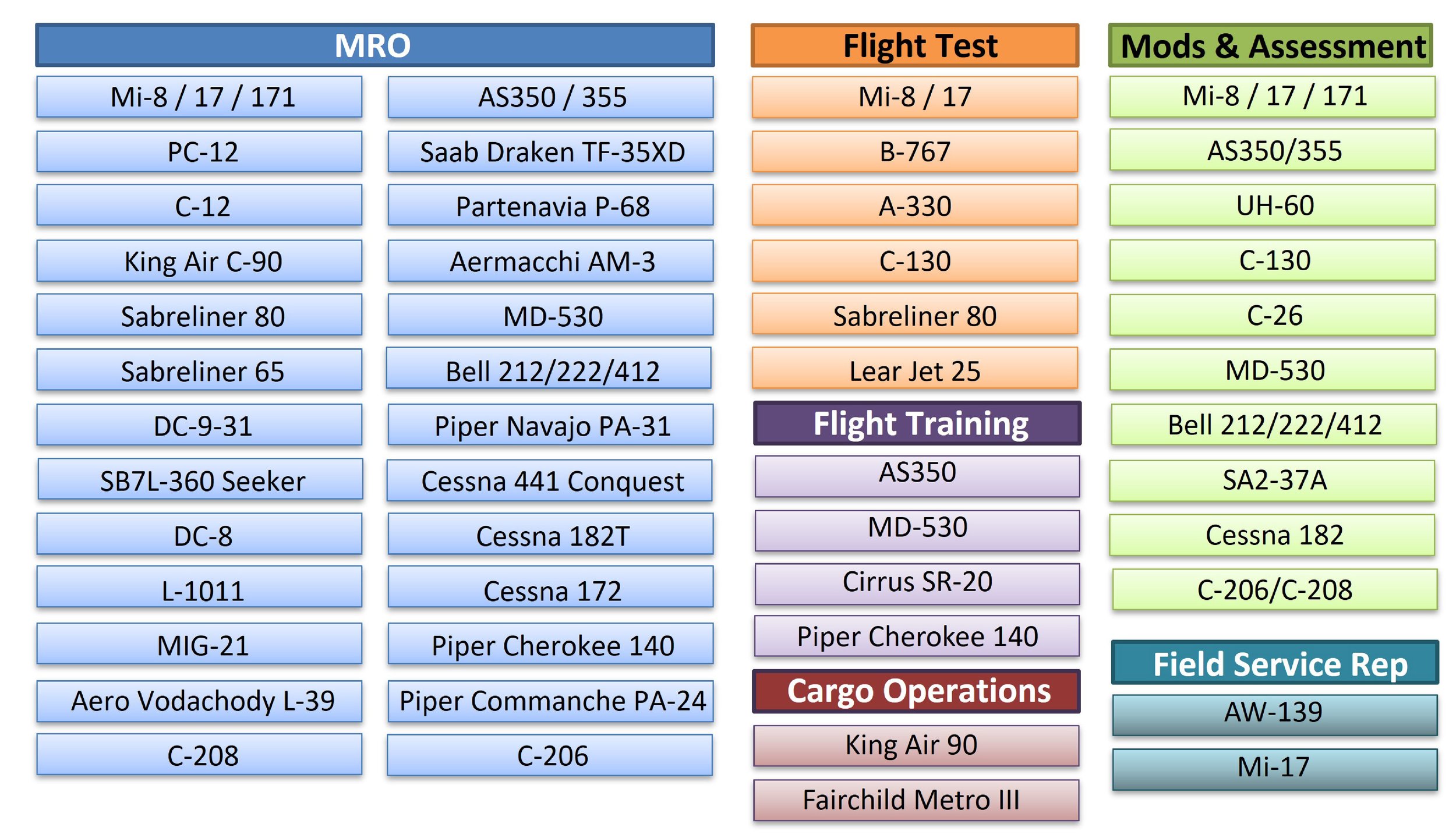

In addition to owning and operating Sabreliner 80, King Air 90, Metroliner III and Piper Cherokee aircraft, FTA has performed services on more than 35 fixed and rotary wing aircraft, including (not all inclusive):

… as well as various Lear, Cessna and Piper fixed-wing platforms. The FTA Team has performed maintenance and repair on a multitude of general, corporate, and commercial aviation aircraft from its FAA certified Repair Stations located (formerly) in Mojave, California and (currently) in Memphis, Tennessee.

Logistics

Operating on a global scale, FTA is particularly experienced with the processes of long logistics chains. FTA owns and operates more than 170,000 ft2 of warehouse space in the U.S. (3 locations), The Netherlands, UAE and Kenya. FTA is fully knowledgeable of global export controls and understands the provisions of the U.S. Export Administration Act (EAA) and International Traffic in Arms Regulations (ITAR) and complies with all export control documentation requirements and import/customs policies and processes.

FTA has a broad range of aviation and specialized technical services on a true international scale, while specializing in on-site services in challenging remote and hostile locations. FTA thoroughly understands the complexities of global logistics. Its foreign-registered business offices, warehouses, and depots provide a comprehensive, fully-developed global aviation support services and logistics supplier network. The skilled foreign nationals employed by FTA provide sophisticated support for aircraft maintenance and logistics support; these local nationals understand the culture, business laws, customs, and import/export regulations of their respective nations.

Modifications & Upgrades

Our engineers have developed 6 FAA Supplemental Type Certificates (STCs) for various improvements related to 7 fixed-wing aircrafts. Further, FTA’s engineers have performed fleet technical assessments on a multitude of rotary and fixed wing aircraft and designed hardware and test plans for avionics modifications. Among FTA’s aircraft modification and upgrade activities have been:

· ISR systems (Radar, EO/IR, Thermal, NVIS, MCFDs)

· Glass Cockpits

· HF Radio and ICS

· Various Comms/Nav Antennas (SATCOM, HF, GPS, ILS, Transponders, ICS, DVRs/FDRs, )

· Night Vision Lighting (Exterior and Interior)

· Ballistic Protection (Exterior and Interior)

· Missile Warning & Gunshot Detection

· Gun Mounts

· Search and Rescue (SAR) Equipment

· Data Acquisition Systems

· Cargo Access Doors

Training

During 2001 through 2009, experienced FTA technicians provided extensive training to Colombian military and special operations forces on field (remote/austere environment) maintenance, operations and sustainment of the TigerShark UAS.

In 2011, FTA provided Night Vision Goggle (NVG) training for Kazakhstan Border Guard Service pilots and maintenance technicians.

Since 2017, FTA has implemented a well-oiled mentoring and on-the-job aviation training program for the AAF and SMW. This program takes the personnel of the Afghan maintenance team and progresses them through a stair-step proficiency level development program from novice to expert technician. FTA trainers work side by side with Afghan students during a multi-year development process culminating in the AAF capability to independently perform all maintenance inspections.

Additionally, in 2019, FTA commenced support to the U.S. Army PEO for Simulation, Training and Instrumentation (PEO STRI). FTA trains an audience of over 100 customer personnel with nearly 30 full time trainers from various nations working to train Afghan military/special operations personnel in various tasks from staff work, to kinetic targeting, to special operations activities, and not least of which in MD-530 pilot training.

Most recently in 2020, FTA began a contract supporting the U.S. Air Force Predator pilot proficiency training.

Unmanned Aerial Vehicles/Systems

FTA has performed payload design, fabrication, installation, integration, and test & evaluation, as well as maintenance and logistics, for the Predator and Pioneer UAVs. Additionally, FTA has on staff three highly-experienced UAV/UAS technicians with extensive qualifications maintaining and operating the TigerShark, Hunter, Kaman 1200 (K-MAX), Shadowhawk, Stalker XE and Desert Hawk platforms. These operations have taken place in Afghanistan, Libya, Kenya, Uganda and Colombia supporting special operations, intelligence collection, pipeline protection, convoy protection, and counter-narcotics operations, and have included maintenance, aircraft/system modifications and logistics sustainment as well as operations. UAV/UAS modifications have included: EO/IR, GMTI/SAR, SATCOM (encrypted, both audio and video), DF Arrays, Counter satellite, and COMINT and SIGINT packages and antenna arrays. The effort in Colombia included training the Colombians on maintenance, operations, logistics and data link and video/data relays.